That makes sense with the tool changes thanks for the explanation. Thank you, yes grbI am using the BlackBox Controller and a bone stock Lead 1010 with Dewalt 611.

You should probably watch some CAM videos from NYC CNC and Lars Christensen first. I assumed you used fusion cam before, but sounds like you havent. If you dont fusion will generate a toolpath to cut the entire part. So, if your part is bigger than your machine, you are responsible for containing toolpaths. Fusion doesnt care what machine you are using. You set up your speeds and feeds for each operation. If you hover your mouse over them, they should explain what they are for. Regardless of who's post you use, make sure you read and understand the post properties so you wont be surprised where the machine moves after job completion.

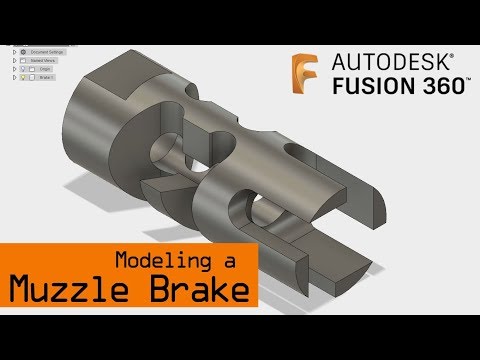

Its probably time to get it merged with the swarfer post, but in the meantime, its here: sharmstr/GRBL-Post-Processor It will auto create a new file for every tool change for you so you only need to post once. I've modified the swarfer post to make it easier to handle tool changes. You need a separate gcode file for every tool change. Just today I found out that Fusion has a bunch of 'hidden' tolerance settings that can be accessed by right-clicking on a toolpath and then choosing 'compare and edit' and filtering the parameters by 'tolerance', which gives you this:So, I'm assuming you are using a grbl based controller. Apparently this is fairly common with CAM software, I just didn't realize that was how it worked.Īfter that revelation I started paying a lot more attention to the 'tolerance' setting in the Fusion toolpath dialog as it directly impacts how finely the mesh is generated, and found that setting it to very small values (0.00001mm) drastically improved the quality of my surface finishes, at the expense of much longer times for computing the toolpaths. However I recently found out Fusion 360 does not create toolpaths directly from the solid model, instead it creates a mesh of the model first and then makes the toolpaths from that. For the longest time I thought that my 'old' Fadals simply weren't capable of creating really high quality surface finishes, I would always get small inconsistencies in between passes when doing a finishing toolpath, and that would leave divots and so on that I'd have to hand finish out.

0 kommentar(er)

0 kommentar(er)